Revolutionize Your Roof: Unvented Insulation Measuring Sticks for Maximum Efficiency

Introduction

Ensuring your unvented roof performs at peak efficiency starts with accurate measurement of blown-in insulation. Unvented insulation measuring sticks are indispensable tools that guarantee you install the correct insulation depth every time. By combining seamless coverage with precise depth readings, these measuring sticks help homeowners and contractors achieve optimal thermal performance, soundproofing, and energy savings in unvented roof spaces.

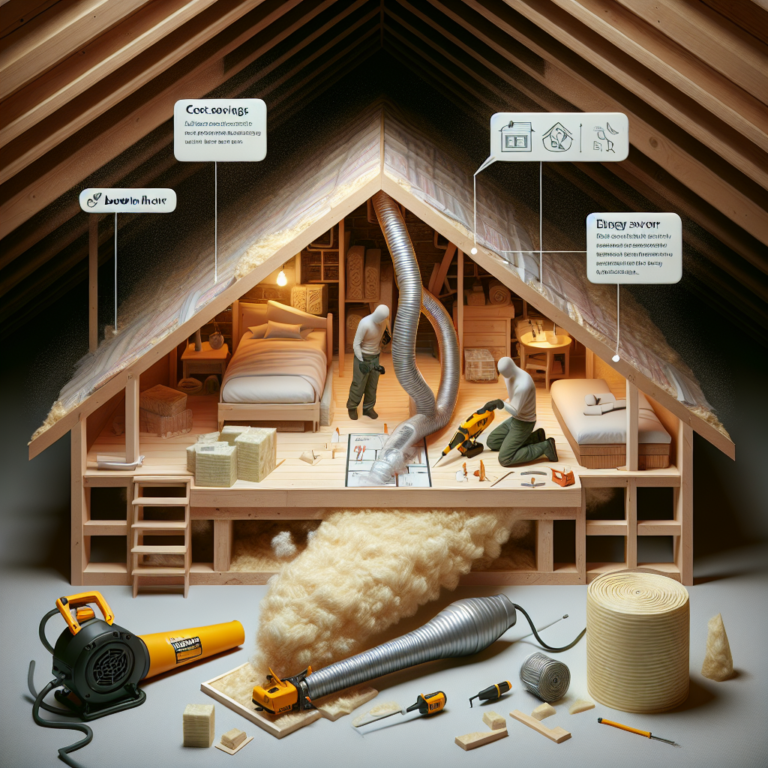

H2: Why Blown-In Insulation Suits Unvented Roof Spaces

Blown-in insulation has surged in popularity for unvented roof assemblies. When you seal off your roof deck from exterior air movement, blown-in fiberglass or cellulose becomes the ideal solution to fill every gap, void, and irregular angle in the roof cavity. Key benefits include:

• Seamless coverage—Loose-fill insulation conforms to rafters, joists, and odd angles, preventing thermal leaks that rigid batts might miss.

• Superior R-value—The trapped air pockets within blown-in material deliver outstanding resistance to heat flow, stabilizing indoor temperatures year-round.

• Sound attenuation—By absorbing airborne noise from rain, wind, and outside sources, blown-in insulation transforms your attic into a quieter, more comfortable buffer zone.

• Eco-friendly composition—Many blown-in products contain recycled content, while the installation process generates minimal waste.

• Cost efficiency—Lower material costs and rapid installation translate into a faster project turnaround and immediate energy-bill savings.

H2: How Unvented Insulation Measuring Sticks Ensure Precision

Unvented insulation measuring sticks take the guesswork out of achieving the proper insulation depth. Here’s how they work:

1. Marked Depth Indicators—Graduated markings correspond to insulation thickness (for example, R-value requirements), so you know exactly when you’ve reached the correct level.

2. Durable Construction—Available in fiberglass, aluminum, or plastic, these sticks resist moisture and bending, maintaining accuracy over repeated uses.

3. Easy Insertion—Slim profiles let you probe tight cavities without disrupting insulation fibers, ensuring a smooth, uninterrupted measurement.

4. Quick Verification—By sampling multiple points across the attic, you can confirm consistent coverage and identify thin spots before sealing the roof deck.

H2: Selecting the Best Unvented Insulation Measuring Sticks

Choosing the right measuring stick is critical for reliable results. Consider these factors:

• Material—Fiberglass sticks resist warping and moisture, while aluminum models offer ultra-straight edges but may dent if mishandled. Plastic sticks balance weight and durability.

• Length—Standard options range from 3 to 10 feet. Match stick length to your attic’s maximum insulation depth plus a few inches for handling.

• Scale Precision—Look for sticks with both imperial and metric scales, and clear, easy-to-read markings at least every half-inch (or 10 mm).

• Portability—Telescoping sticks collapse for storage and transport, making them ideal for multi-site contractors.

• Price vs. Longevity—Invest in a well-made measuring stick that withstands rough job-site conditions rather than opting for a brittle, low-cost alternative.

H2: Avoid These Common Pitfalls When Installing Blown-In Insulation

Even with the right tools, mistakes can undermine your insulation’s performance. Sidestep these errors:

• Under- or Over-Insulating—Failing to meet the recommended R-value leaves energy savings on the table; excessive packing can compress fibers and reduce effectiveness.

• Ignoring Ventilation—While unvented roofs eliminate soffit and ridge vents, you still need a proper air seal below the roof deck and a vapor-control layer to prevent moisture buildup.

• Skipping Prep Work—Clear debris, old insulation, and obstruction before blowing in new material. Seal penetrations around pipes, wiring, and ceiling fixtures to maintain air tightness.

• Uneven Distribution—Start blowing from the farthest corner and work toward the access point. Routinely check depth with your unvented insulation measuring sticks to ensure uniform coverage.

• Wrong Insulation Type—Choose cellulose for eco-conscious projects, fiberglass for cost-effectiveness, or mineral wool for superior fire resistance. Each material behaves differently under dense-pack or loose-fill conditions.

H2: Q&A: Everything You Need to Know about Unvented Insulation Measuring Sticks

Q1: What exactly are unvented insulation measuring sticks?

A1: They’re long probes marked with depth graduations that measure insulation thickness in attics, walls, and roof cavities—crucial for verifying R-value and uniform coverage.

Q2: How many measurements should I take?

A2: Sample at least five to ten points across the attic to calculate an accurate average and pinpoint any thin or overpacked zones.

Q3: Can I use the same stick for different insulation types?

A3: Yes. Whether you install cellulose, fiberglass, or mineral wool, the depth-graduated markings help you achieve the target R-value regardless of material.

Conclusion

Accurate measurement is the cornerstone of a high-performance unvented roof system. By integrating unvented insulation measuring sticks into your workflow, you’ll guarantee the correct insulation depth, optimal thermal efficiency, and long-term comfort. Measure with confidence, insulate with precision—and revolutionize your roof’s energy performance today.