-

Table of Contents

“Measure and insulate with precision using our blow-in insulation ruler!”

Introduction

Blow-in insulation rulers are specialized tools used in the installation of blow-in insulation. This type of insulation is typically made of loose fibers or particles, such as cellulose, fiberglass, or mineral wool, that are blown into walls, attics, or other spaces to provide thermal and sound insulation. The ruler is used to measure the depth of the insulation as it is being blown in, ensuring that the desired amount is evenly distributed throughout the space. This tool is essential for achieving proper insulation levels and maximizing energy efficiency in buildings. In this introduction, we will explore the purpose and function of blow-in insulation rulers in more detail.

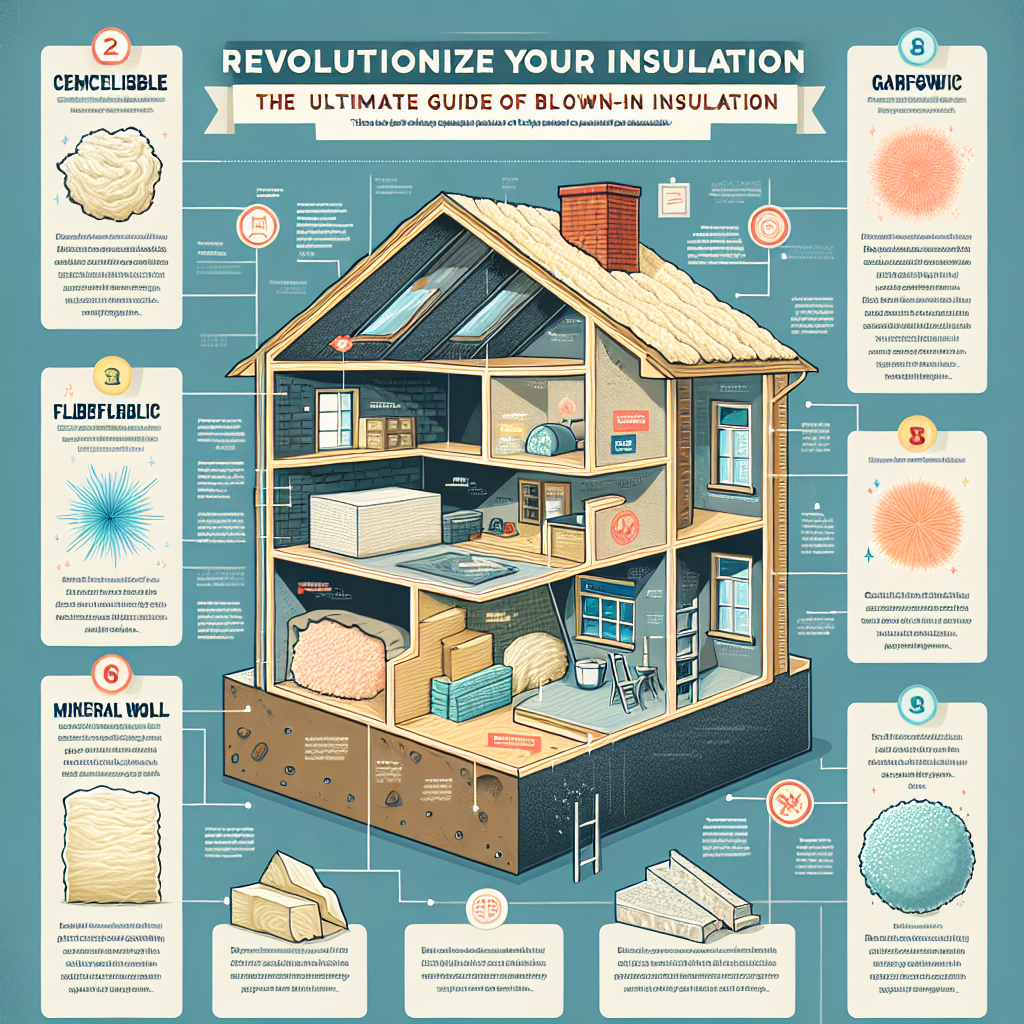

Different Types of Blown-In Insulation: A Comprehensive Guide

Blown-in insulation is a popular choice for homeowners looking to improve the energy efficiency of their homes. It is a cost-effective and efficient way to insulate attics, walls, and other areas of the home. One of the key tools used in the installation of blown-in insulation is the insulation ruler. This simple yet essential tool helps ensure that the insulation is installed at the correct depth, providing maximum effectiveness. In this article, we will explore the different types of blown-in insulation and how the insulation ruler plays a crucial role in their installation.

There are three main types of blown-in insulation: fiberglass, cellulose, and mineral wool. Each type has its own unique properties and benefits, but they all share the same goal of improving the energy efficiency of a home. Fiberglass insulation is made of tiny glass fibers and is the most commonly used type of blown-in insulation. It is lightweight, fire-resistant, and does not settle over time. Cellulose insulation, on the other hand, is made of recycled paper and is treated with fire-retardant chemicals. It is a more environmentally friendly option and has a higher R-value (a measure of insulation’s effectiveness) than fiberglass. Mineral wool insulation is made of rock or slag fibers and is known for its excellent soundproofing capabilities.

Regardless of the type of blown-in insulation used, the installation process is similar. The insulation is blown into the desired area using a special machine. This is where the insulation ruler comes into play. The ruler is a long, thin piece of metal or plastic with markings that indicate the depth of the insulation. It is placed in the area where the insulation is being blown, and the installer uses it as a guide to ensure that the insulation is installed at the correct depth.

The correct depth of blown-in insulation is crucial for its effectiveness. If the insulation is not installed at the recommended depth, it can lead to air gaps and reduce its ability to trap heat. This is where the insulation ruler becomes an essential tool. It helps the installer achieve the desired depth, ensuring that the insulation is evenly distributed and providing maximum coverage.

The depth of insulation required varies depending on the type of insulation used and the climate of the area. For fiberglass insulation, the recommended depth is typically between 12-14 inches, while cellulose insulation requires a depth of 10-12 inches. Mineral wool insulation, on the other hand, needs to be installed at a depth of 8-10 inches. The insulation ruler makes it easy for installers to measure and achieve the correct depth, ensuring that the insulation is installed correctly and effectively.

In addition to helping achieve the correct depth, the insulation ruler also helps with the overall installation process. It allows for a more precise and consistent installation, reducing the chances of gaps or uneven coverage. This is especially important in areas with obstructions, such as pipes or electrical wires, where the installer needs to work around them to ensure complete coverage.

In conclusion, blown-in insulation is an excellent choice for homeowners looking to improve the energy efficiency of their homes. The three main types of blown-in insulation, fiberglass, cellulose, and mineral wool, all require the use of an insulation ruler during installation. This simple yet essential tool helps achieve the correct depth of insulation, ensuring maximum effectiveness. It also allows for a more precise and consistent installation, making it a crucial tool for any insulation project. So, if you are considering blown-in insulation for your home, make sure to ask your installer about the use of an insulation ruler to ensure a successful and efficient installation.

Understanding the Benefits of Blown-In Insulation for Your Home

Blown-in insulation has become a popular choice for homeowners looking to improve the energy efficiency of their homes. This type of insulation involves using a machine to blow loose insulation material into the walls, attic, or other areas of a home. One tool that is essential for this process is the blow-in insulation ruler. In this article, we will explore the benefits of blown-in insulation and how the use of a blow-in insulation ruler can make the process even more effective.

One of the main benefits of blown-in insulation is its ability to fill in small gaps and crevices that traditional insulation methods may miss. This is especially important in older homes where there may be uneven or irregularly shaped spaces. The loose insulation material can easily conform to these spaces, creating a more complete and effective barrier against heat loss or gain.

Another advantage of blown-in insulation is its ability to provide a higher R-value, or thermal resistance, compared to other types of insulation. This means that it can better resist the transfer of heat, keeping your home cooler in the summer and warmer in the winter. The use of a blow-in insulation ruler can help ensure that the proper amount of insulation is being installed, resulting in a higher R-value and greater energy savings.

In addition to its energy-saving benefits, blown-in insulation also has soundproofing properties. The loose material can absorb sound waves, reducing noise from outside sources and creating a quieter and more comfortable living space. This is especially beneficial for homes located in busy or noisy areas.

One of the most significant advantages of blown-in insulation is its cost-effectiveness. The installation process is relatively quick and straightforward, which can save homeowners both time and money. Additionally, the loose material can be blown into existing walls without the need for major renovations, making it a more affordable option compared to other insulation methods.

Furthermore, blown-in insulation is environmentally friendly. The material used is often made from recycled materials, reducing the amount of waste that ends up in landfills. It also helps to reduce energy consumption, which in turn reduces the carbon footprint of a home. By using a blow-in insulation ruler to ensure the proper amount of insulation is installed, homeowners can further contribute to a more sustainable and eco-friendly living space.

Another benefit of blown-in insulation is its ability to resist moisture. The loose material is not affected by water, making it an ideal choice for areas prone to high humidity or moisture. This can help prevent the growth of mold and mildew, which can be harmful to both the home and its occupants.

Finally, blown-in insulation can also improve the overall comfort of a home. By creating a more consistent temperature throughout the house, it eliminates cold spots and drafts, making it more comfortable for residents. This can also lead to a reduction in energy bills, as the heating and cooling systems do not have to work as hard to maintain a comfortable temperature.

In conclusion, blown-in insulation offers numerous benefits for homeowners, from energy efficiency and cost-effectiveness to soundproofing and environmental friendliness. The use of a blow-in insulation ruler can further enhance these benefits by ensuring the proper amount of insulation is installed, resulting in a more effective and efficient insulation barrier. If you are considering improving the insulation in your home, be sure to explore the option of blown-in insulation and the use of a blow-in insulation ruler for maximum benefits.

Choosing the Right Blown-In Insulation Ruler for Your Insulation Project

When it comes to insulating your home, there are many options available. One popular choice is blown-in insulation, which involves using a machine to blow loose insulation material into your walls, attic, or other areas of your home. This method is known for its effectiveness in filling small gaps and crevices, providing better coverage and energy efficiency compared to traditional batt insulation. However, in order to achieve the best results, it is important to choose the right blown-in insulation ruler for your project.

First and foremost, it is crucial to understand the purpose of a blown-in insulation ruler. This tool is used to measure the depth of the insulation material once it has been blown into the desired area. This is important because the depth of the insulation directly affects its R-value, which is a measure of its thermal resistance. The higher the R-value, the better the insulation is at preventing heat transfer. Therefore, having an accurate measurement of the insulation depth is essential for achieving optimal energy efficiency in your home.

When it comes to choosing the right blown-in insulation ruler, there are a few factors to consider. The first is the type of insulation material you will be using. Different materials have different densities, which can affect the depth of the insulation once it is blown in. For example, fiberglass insulation is less dense than cellulose insulation, so it will require a different ruler to achieve the same depth. It is important to consult with your insulation contractor or the manufacturer of the insulation material to determine the appropriate ruler for your specific project.

Another factor to consider is the size of the ruler. Blown-in insulation rulers come in various lengths, typically ranging from 4 feet to 10 feet. The length you choose will depend on the size of the area you will be insulating. For smaller areas, a shorter ruler may be sufficient, while larger areas may require a longer ruler to ensure accurate measurements. It is also important to consider the width of the ruler, as a wider ruler may be more stable and easier to use compared to a narrower one.

In addition to the length and width, the material of the ruler is also important. Most blown-in insulation rulers are made of durable materials such as aluminum or plastic. Aluminum rulers are known for their strength and rigidity, making them a popular choice among contractors. Plastic rulers, on the other hand, are lightweight and may be more affordable, but they may not be as durable as aluminum rulers. Ultimately, the material you choose will depend on your personal preference and the specific needs of your project.

It is also worth noting that some blown-in insulation rulers come with additional features, such as a built-in level or a handle for easier maneuvering. While these features may be convenient, they are not necessary for achieving accurate measurements. Therefore, it is important to weigh the cost and benefits of these additional features before making a decision.

In conclusion, choosing the right blown-in insulation ruler is crucial for achieving optimal energy efficiency in your home. Factors such as the type of insulation material, the size and material of the ruler, and any additional features should be considered when making your selection. Consulting with your insulation contractor or the manufacturer of the insulation material can also help ensure that you have the right ruler for your specific project. With the right tools and materials, you can achieve a well-insulated home that will save you money on energy bills and provide a comfortable living space for years to come.

Q&A

Q: What is a blow in insulation ruler?

A: A blow in insulation ruler is a tool used to measure the depth of blown-in insulation in attics or walls.

Q: How is a blow in insulation ruler used?

A: A blow in insulation ruler is inserted into the insulation material and the depth is measured by reading the markings on the ruler.

Q: Why is a blow in insulation ruler important?

A: A blow in insulation ruler ensures that the proper amount of insulation is installed, which helps improve energy efficiency and reduce heating and cooling costs.

Conclusion

In conclusion, using a blow-in insulation ruler is an effective and efficient way to ensure proper installation of insulation in a building. It allows for accurate measurement and distribution of insulation material, resulting in improved energy efficiency and cost savings. Additionally, the use of a blow-in insulation ruler can help reduce the risk of air leaks and moisture buildup, leading to a more comfortable and healthier living environment. Overall, incorporating a blow-in insulation ruler into insulation installation processes can greatly benefit both homeowners and building professionals.