-

Table of Contents

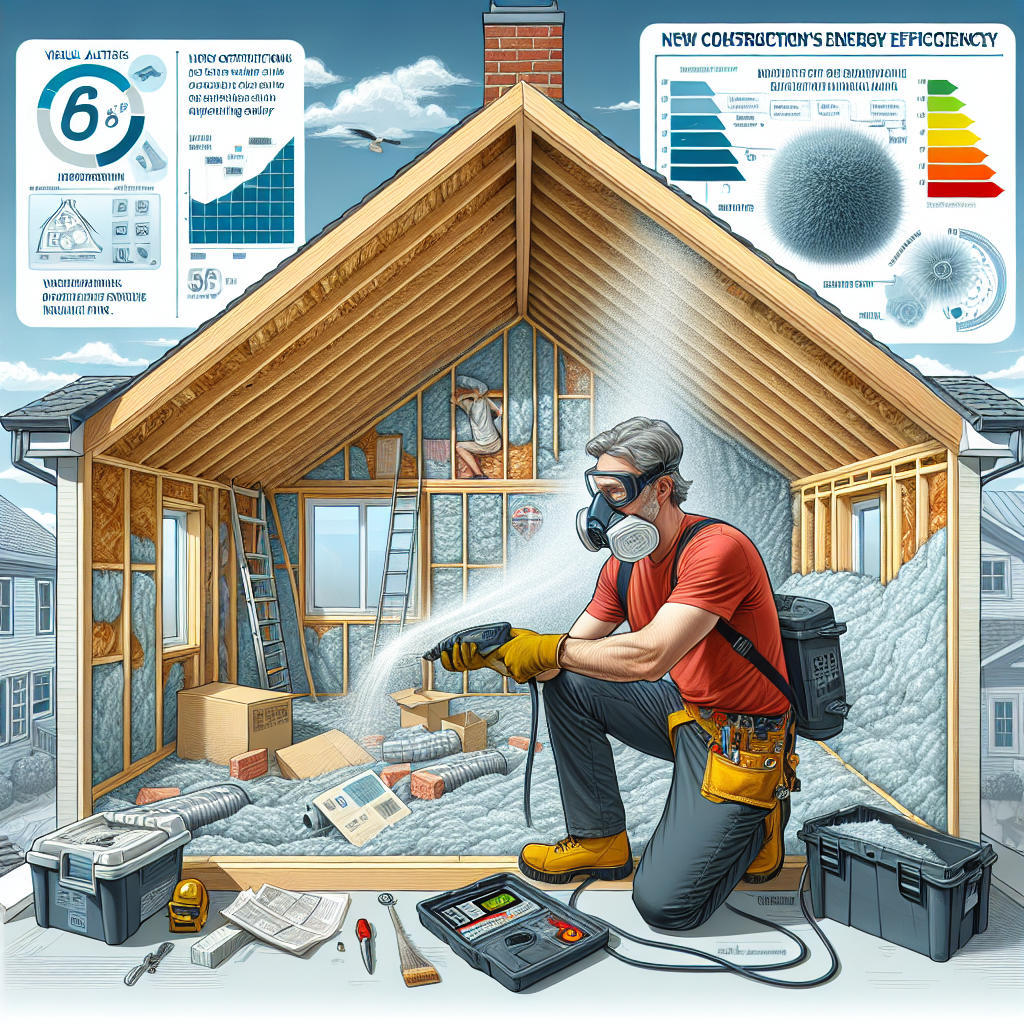

Efficiently insulate your new construction with DIY blown-in wall insulation.

Introduction

DIY blown in wall insulation is a popular method for insulating new construction projects. It involves using loose insulation material, such as fiberglass or cellulose, and blowing it into the walls of a building. This technique is often preferred for its ease of installation and cost-effectiveness. In this introduction, we will explore the benefits and process of DIY blown in wall insulation for new construction.

Top 3 Types of Blown-In Wall Insulation for New Construction

When it comes to new construction, insulation is a crucial element that should not be overlooked. Proper insulation not only helps to regulate the temperature inside the building, but it also plays a significant role in reducing energy costs. One popular method of insulation for new construction is blown-in wall insulation. This type of insulation involves blowing loose insulation material into the walls, filling up any gaps and creating a barrier against heat transfer. In this article, we will discuss the top three types of blown-in wall insulation for new construction.

1. Fiberglass Blown-In Insulation

Fiberglass is a popular choice for blown-in wall insulation due to its affordability and effectiveness. It is made up of tiny glass fibers that are blown into the walls using a special machine. The fibers are then compacted together, creating a dense layer of insulation. Fiberglass insulation is known for its high R-value, which measures the material’s ability to resist heat flow. This means that it can effectively keep the heat inside during the winter and outside during the summer, making it an energy-efficient option.

One of the main advantages of fiberglass blown-in insulation is its ability to fill up even the smallest gaps and crevices in the walls. This ensures that there are no air leaks, which can significantly impact the insulation’s effectiveness. Additionally, fiberglass is non-combustible, making it a safe option for new construction. However, it is essential to note that fiberglass can cause skin irritation and respiratory issues if not installed properly. Therefore, it is recommended to hire a professional for the installation process.

2. Cellulose Blown-In Insulation

Cellulose insulation is made from recycled paper and treated with fire-retardant chemicals, making it a more environmentally friendly option compared to fiberglass. It is also known for its high R-value, making it an effective insulator for new construction. Cellulose insulation is blown into the walls using a machine, similar to fiberglass. However, it requires less energy to produce, making it a more energy-efficient option.

One of the main advantages of cellulose blown-in insulation is its ability to reduce noise transmission. The dense layer of insulation helps to absorb sound, making it an ideal choice for buildings located in noisy areas. Additionally, cellulose is treated with borate, a natural insect repellent, making it resistant to pests and mold. However, it is essential to note that cellulose insulation can settle over time, reducing its effectiveness. Therefore, it is recommended to have it installed by a professional who can ensure proper installation and avoid any settling.

3. Mineral Wool Blown-In Insulation

Mineral wool, also known as rock wool, is made from natural minerals such as basalt and diabase. It is a popular choice for blown-in wall insulation due to its high R-value and fire-resistant properties. Mineral wool is blown into the walls using a machine, similar to fiberglass and cellulose. It is known for its ability to withstand high temperatures, making it an ideal choice for buildings that require fire-resistant insulation.

One of the main advantages of mineral wool blown-in insulation is its ability to repel water. This makes it an ideal choice for buildings located in areas with high humidity or prone to flooding. Additionally, mineral wool is resistant to pests and mold, making it a durable option for new construction. However, it is essential to note that mineral wool can be more expensive compared to other types of blown-in insulation.

In conclusion, blown-in wall insulation is an effective and energy-efficient option for new construction. Whether you choose fiberglass, cellulose, or mineral wool, each type has its unique advantages and can provide excellent insulation for your building. It is essential to consult with a professional to determine the best type of insulation for your specific needs and ensure proper installation for maximum effectiveness. With the right insulation, you can create a comfortable and energy-efficient space for your new construction project.

DIY Guide: How to Install Blown-In Wall Insulation in a New Construction Home

Insulating your home is an essential step in creating a comfortable and energy-efficient living space. While most new construction homes come with standard insulation, it may not be enough to keep your home properly insulated. This is where blown-in wall insulation comes in. It is a cost-effective and efficient way to add insulation to your walls, ensuring that your home stays warm in the winter and cool in the summer. In this DIY guide, we will walk you through the steps of installing blown-in wall insulation in a new construction home.

Before we dive into the installation process, it is essential to understand what blown-in wall insulation is and how it works. Blown-in insulation is made of small particles of materials such as fiberglass, cellulose, or mineral wool. These particles are blown into the wall cavities using a special machine, filling up any gaps and creating a barrier against heat transfer. This type of insulation is ideal for new construction homes as it can be easily installed in walls that are already built.

The first step in installing blown-in wall insulation is to gather all the necessary materials and tools. You will need a blower machine, insulation material, a utility knife, a staple gun, and a ladder. It is also crucial to wear protective gear, such as gloves, goggles, and a dust mask, to avoid any contact with the insulation material.

Next, you will need to prepare the walls for insulation. This involves making sure that all wall cavities are free of debris, such as dust, dirt, and any other obstructions. You can use a vacuum cleaner to clean out the cavities and ensure that they are clear and ready for insulation.

Once the walls are prepped, it is time to start the installation process. Start by loading the insulation material into the blower machine. Follow the manufacturer’s instructions on how to operate the machine and adjust the settings according to the type of insulation material you are using. It is essential to wear protective gear at this stage, as the insulation material can be hazardous if inhaled.

Using the blower machine, start filling the wall cavities with the insulation material. Begin at the bottom of the wall and work your way up, making sure to fill each cavity evenly. Use the utility knife to cut the insulation material as needed to fit into smaller cavities or around obstacles such as electrical outlets.

As you fill the cavities, use the staple gun to secure the insulation in place. This will prevent it from settling or shifting over time. Make sure to staple the insulation to the studs, not the drywall, as this can cause damage to the walls.

Once all the cavities are filled and secured, use the utility knife to trim any excess insulation material that may be sticking out of the wall. This will ensure a clean and neat finish.

After the installation is complete, it is essential to clean up any leftover insulation material and debris. Vacuum the area and dispose of the waste properly. You can also use a damp cloth to wipe down any surfaces that may have come in contact with the insulation material.

In conclusion, installing blown-in wall insulation in a new construction home is a relatively simple and cost-effective process. It is an excellent way to improve the energy efficiency of your home and create a comfortable living space. By following these steps and taking the necessary safety precautions, you can successfully install blown-in wall insulation and enjoy the benefits for years to come.

Choosing the Best Blown-In Attic Insulation for Your New Construction Project

When it comes to new construction projects, one of the most important considerations is insulation. Proper insulation not only helps regulate the temperature inside the building, but it also plays a crucial role in energy efficiency and cost savings. While there are various types of insulation available, blown-in wall insulation has gained popularity in recent years due to its ease of installation and effectiveness. In this article, we will discuss the benefits of DIY blown-in wall insulation for new construction projects and provide tips for choosing the best option for your specific needs.

First and foremost, let’s understand what blown-in wall insulation is. As the name suggests, it involves blowing insulation material into the walls of a building. This method is typically used for new construction projects as it allows for easy installation before the walls are closed up. The insulation material is blown into the walls using specialized equipment, filling up any gaps and creating a seamless layer of insulation. This method is particularly useful for hard-to-reach areas and irregularly shaped spaces, ensuring complete coverage and maximum efficiency.

One of the main benefits of blown-in wall insulation is its ability to provide a high level of thermal resistance. This means that it can effectively prevent heat transfer, keeping the interior of the building warm in the winter and cool in the summer. This, in turn, reduces the need for heating and cooling systems, resulting in significant energy savings. Additionally, blown-in insulation is known for its soundproofing capabilities, making it an ideal choice for buildings located in noisy areas or for those looking to create a quiet and peaceful environment.

Another advantage of blown-in wall insulation is its eco-friendliness. Most blown-in insulation materials are made from recycled materials, making them a sustainable choice for new construction projects. They also have a longer lifespan compared to other types of insulation, reducing the need for frequent replacements and minimizing waste. Furthermore, blown-in insulation does not contain harmful chemicals, making it safe for both the environment and the occupants of the building.

Now that we have established the benefits of blown-in wall insulation, let’s discuss how to choose the best option for your new construction project. The first step is to determine the R-value, which is a measure of thermal resistance. The higher the R-value, the better the insulation’s ability to resist heat transfer. The R-value required for your project will depend on factors such as climate, building design, and local building codes. It is essential to consult with a professional to determine the appropriate R-value for your specific needs.

Next, consider the type of insulation material. The most commonly used materials for blown-in wall insulation are fiberglass, cellulose, and mineral wool. Fiberglass is a popular choice due to its affordability and high R-value. Cellulose, on the other hand, is made from recycled paper and has excellent soundproofing capabilities. Mineral wool, also known as rock wool, is a more expensive option but offers superior fire resistance.

In addition to the material, consider the installation process and equipment required. DIY blown-in wall insulation kits are available for purchase, but they may not be suitable for larger projects. It is crucial to have the right equipment and knowledge to ensure proper installation and maximum efficiency. If you are unsure, it is best to hire a professional insulation contractor to do the job.

In conclusion, blown-in wall insulation is an excellent choice for new construction projects due to its ease of installation, effectiveness, and eco-friendliness. When choosing the best option for your project, consider factors such as R-value, insulation material, and installation process. With the right insulation, you can create a comfortable and energy-efficient building that will stand the test of time.

Q&A

Q: What is blown in wall insulation?

A: Blown in wall insulation is a type of insulation that is installed by blowing loose fibers or particles into the walls of a building. This method is commonly used in new construction projects.

Q: How is blown in wall insulation installed in new construction?

A: Blown in wall insulation is typically installed by drilling small holes into the walls and then using a machine to blow the insulation material into the cavities. The holes are then patched up and the walls are finished as usual.

Q: What are the benefits of using blown in wall insulation in new construction?

A: Blown in wall insulation can provide better coverage and fill in any gaps or voids in the walls, resulting in improved energy efficiency and lower utility bills. It can also help reduce noise transmission and improve indoor air quality. Additionally, it is a cost-effective and environmentally friendly option for insulation.

Conclusion

In conclusion, DIY blown-in wall insulation can be a cost-effective and efficient option for new construction projects. It provides excellent thermal and sound insulation, as well as being easy to install. However, it is important to carefully follow instructions and safety precautions to ensure proper installation and avoid any potential hazards. Overall, DIY blown-in wall insulation can be a great choice for new construction projects looking for an affordable and effective insulation solution.