-

Table of Contents

- Introduction

- Benefits of Blown In Insulation for New Construction: Discuss the advantages of using blown in insulation between floor joists in new construction projects. This could include improved energy efficiency, reduced air leakage, and better soundproofing

- Installation Process for Blown In Insulation: Provide a step-by-step guide on how to properly install blown in insulation between floor joists in new construction. This could include tips on equipment needed, safety precautions, and best practices for achieving optimal results

- Comparing Blown In Insulation to Other Types of Insulation: Compare blown in insulation to other commonly used types of insulation in new construction, such as batt or spray foam. Discuss the pros and cons of each and why blown in insulation may be the best choice for certain projects

- Q&A

- Conclusion

“Efficiently insulate your floors with blown in insulation between joists – keeping your home comfortable and energy efficient.”

Introduction

Blown-in insulation is a popular method of insulating the space between floor joists in homes and buildings. This type of insulation involves using loose fibers or particles, such as fiberglass, cellulose, or mineral wool, and blowing them into the space between the joists. This creates a layer of insulation that helps to regulate temperature and reduce energy costs. In this introduction, we will explore the benefits and process of using blown-in insulation between floor joists.

Benefits of Blown In Insulation for New Construction: Discuss the advantages of using blown in insulation between floor joists in new construction projects. This could include improved energy efficiency, reduced air leakage, and better soundproofing

Blown in insulation has become a popular choice for new construction projects, especially when it comes to insulating between floor joists. This method involves using a machine to blow loose insulation material into the spaces between the joists, creating a seamless layer of insulation. While traditional methods of insulation, such as batt or roll insulation, have been used for decades, blown in insulation offers several advantages that make it a preferred choice for many builders and homeowners.

One of the main benefits of blown in insulation between floor joists is its ability to improve energy efficiency. The spaces between floor joists are notorious for allowing air to leak in and out, which can significantly impact the heating and cooling of a building. Blown in insulation fills these gaps and creates a tight seal, preventing air from escaping and reducing the amount of energy needed to maintain a comfortable temperature. This can result in significant cost savings on energy bills, making it a wise investment for new construction projects.

In addition to improving energy efficiency, blown in insulation also helps to reduce air leakage. Air leakage occurs when outside air enters a building through cracks and gaps, and can lead to drafts, uneven temperatures, and even moisture issues. By filling the spaces between floor joists with blown in insulation, the chances of air leakage are greatly reduced. This not only helps to maintain a more consistent temperature but also improves indoor air quality by preventing outside pollutants from entering the building.

Another advantage of using blown in insulation between floor joists is its ability to provide better soundproofing. In new construction projects, it is essential to consider the acoustics of a building, especially in multi-family units or commercial spaces. Blown in insulation helps to absorb sound waves, reducing noise transfer between floors and rooms. This can create a more peaceful and comfortable living or working environment for occupants.

Furthermore, blown in insulation is a more environmentally friendly option compared to traditional insulation methods. The loose insulation material used in this method is typically made from recycled materials, such as shredded newspaper or cellulose fibers. This not only reduces waste but also decreases the demand for new materials, making it a sustainable choice for new construction projects. Additionally, blown in insulation is known for its longevity, meaning it will not need to be replaced as frequently as other types of insulation, further reducing its environmental impact.

Aside from its practical benefits, blown in insulation also offers convenience during the construction process. The use of a machine to blow in the insulation allows for a quick and efficient installation, saving time and labor costs. It also eliminates the need for cutting and fitting insulation around obstacles, such as pipes and electrical wires, as the loose material can easily fill these spaces. This makes it an ideal choice for new construction projects where time and efficiency are crucial.

In conclusion, blown in insulation between floor joists offers numerous advantages for new construction projects. From improved energy efficiency and reduced air leakage to better soundproofing and environmental sustainability, it is a wise investment for any builder or homeowner. Its convenience and ease of installation also make it a preferred choice for construction projects. With its many benefits, it is no surprise that blown in insulation has become a popular option for insulating between floor joists in new construction.

Installation Process for Blown In Insulation: Provide a step-by-step guide on how to properly install blown in insulation between floor joists in new construction. This could include tips on equipment needed, safety precautions, and best practices for achieving optimal results

Blown in insulation is a popular choice for insulating homes, as it provides excellent coverage and can easily fill in small gaps and crevices. One area where blown in insulation is commonly used is between floor joists in new construction. This method of insulation not only helps to keep the home warm in the winter and cool in the summer, but it also helps to reduce energy costs. In this article, we will provide a step-by-step guide on how to properly install blown in insulation between floor joists in new construction.

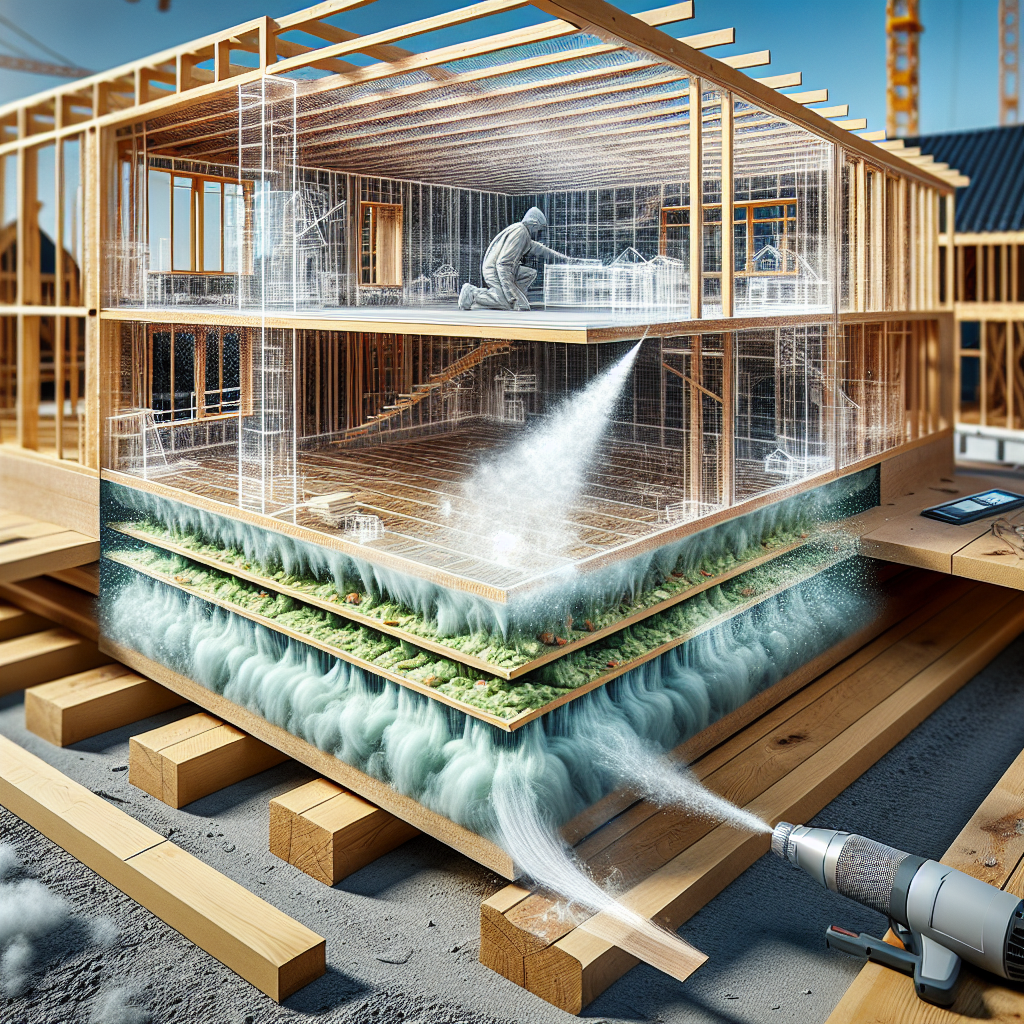

Step 1: Gather the Necessary Equipment

Before beginning the installation process, it is important to gather all the necessary equipment. This includes a blower machine, insulation material, a hose, and protective gear such as goggles, gloves, and a dust mask. It is also important to have a ladder or scaffolding to reach the floor joists.

Step 2: Prepare the Area

Before installing the insulation, it is important to prepare the area. This includes removing any debris or obstructions from the floor joists. It is also important to ensure that the area is dry and free of any moisture, as this can affect the effectiveness of the insulation.

Step 3: Set Up the Blower Machine

Next, set up the blower machine according to the manufacturer’s instructions. This typically involves attaching the hose to the machine and securing it in place. It is important to make sure that the hose is securely attached to the machine to prevent any air leaks.

Step 4: Load the Insulation Material

Once the blower machine is set up, it is time to load the insulation material. This can be done by pouring the material into the hopper of the blower machine. It is important to follow the manufacturer’s instructions for the correct amount of insulation material to use.

Step 5: Begin Blowing in the Insulation

With the blower machine loaded and ready, it is time to start blowing in the insulation. Begin at one end of the floor joist and work your way across, making sure to evenly distribute the insulation material. It is important to wear protective gear during this process, as the insulation material can be irritating to the skin and lungs.

Step 6: Fill in Any Gaps or Crevices

As you work your way across the floor joists, be sure to fill in any gaps or crevices with the insulation material. This will help to ensure that there are no areas where air can escape, providing optimal insulation for the home.

Step 7: Repeat the Process for Each Floor Joist

Continue this process for each floor joist until the entire area is filled with insulation. It is important to take breaks as needed and to refill the blower machine with insulation material as necessary.

Step 8: Clean Up and Dispose of Excess Material

Once all the floor joists are filled with insulation, it is important to clean up any excess material. This can be done by sweeping or vacuuming the area. It is also important to properly dispose of any excess insulation material according to local regulations.

In conclusion, installing blown in insulation between floor joists in new construction is a relatively simple process that can provide numerous benefits for homeowners. By following these steps and taking the necessary safety precautions, you can achieve optimal results and enjoy a well-insulated home. Remember to always consult the manufacturer’s instructions and local building codes for specific guidelines and best practices. With proper installation, blown in insulation can help to keep your home comfortable and energy-efficient for years to come.

Comparing Blown In Insulation to Other Types of Insulation: Compare blown in insulation to other commonly used types of insulation in new construction, such as batt or spray foam. Discuss the pros and cons of each and why blown in insulation may be the best choice for certain projects

Insulation is an essential component of any new construction project, as it helps to regulate the temperature and energy efficiency of a building. When it comes to insulating between floor joists, there are several options available, including batt, spray foam, and blown in insulation. Each type has its own unique characteristics and benefits, but in this article, we will focus on comparing blown in insulation to other commonly used types of insulation in new construction.

Batt insulation, also known as fiberglass insulation, is a traditional and widely used form of insulation. It comes in pre-cut panels or rolls and is typically made of glass fibers that are held together by a binding agent. Batt insulation is relatively easy to install, making it a popular choice for DIY projects. However, it can be challenging to fit into tight spaces, such as between floor joists, and may require additional cutting and shaping.

On the other hand, spray foam insulation is a newer and more advanced form of insulation. It is made of a combination of chemicals that react and expand when sprayed onto a surface, creating a tight seal. Spray foam insulation is known for its excellent insulating properties and ability to fill in small gaps and cracks. However, it can be more expensive than other types of insulation and requires professional installation.

Blown in insulation, also known as loose-fill insulation, is made of small particles of materials such as fiberglass, cellulose, or mineral wool. It is installed using a blowing machine, which blows the insulation into the desired space, filling it completely. Blown in insulation is known for its ability to conform to any space, making it an ideal choice for insulating between floor joists. It is also relatively easy to install and can be done by a professional or as a DIY project.

One of the main advantages of blown in insulation is its ability to provide a seamless and continuous layer of insulation. Unlike batt insulation, which can leave gaps and spaces, blown in insulation fills every nook and cranny, providing better coverage and reducing the risk of air leakage. This makes it a more energy-efficient option, as it helps to keep the temperature consistent and reduces the workload on heating and cooling systems.

Another benefit of blown in insulation is its ability to resist moisture. Batt insulation can absorb moisture, which can lead to mold and mildew growth, while spray foam insulation can trap moisture, causing damage to the structure. Blown in insulation, on the other hand, is resistant to moisture and can help to prevent these issues.

In terms of cost, blown in insulation falls somewhere in between batt and spray foam insulation. While it may be more expensive than batt insulation, it is generally more affordable than spray foam insulation. However, the long-term savings on energy bills and the added benefits of better insulation and moisture resistance make it a worthwhile investment.

One potential downside of blown in insulation is that it may settle over time, especially if it is not installed correctly. This can lead to a decrease in its insulating properties and may require additional insulation to be added in the future. However, this can be avoided by hiring a professional installer who has experience with blown in insulation and knows how to properly install it.

In conclusion, when comparing blown in insulation to other types of insulation commonly used in new construction, it is clear that it has several advantages. Its ability to provide a seamless and continuous layer of insulation, resist moisture, and be more cost-effective than spray foam insulation make it a top choice for insulating between floor joists. However, it is essential to consider the specific needs and requirements of each project before deciding on the type of insulation to use. Consulting with a professional can also help in making an informed decision and ensuring that the insulation is installed correctly for maximum effectiveness.

Q&A

Q: What is blown in insulation between floor joists?

A: Blown in insulation between floor joists is a type of insulation that is installed by blowing loose fibers or particles into the space between the floor joists of a building.

Q: What are the benefits of blown in insulation between floor joists?

A: Some benefits of blown in insulation between floor joists include improved energy efficiency, reduced noise transmission, and better temperature control in the building.

Q: How is blown in insulation between floor joists installed?

A: Blown in insulation between floor joists is typically installed using a special machine that blows the insulation material into the space between the joists. The process is quick and efficient, and can be done without major disruption to the building.

Conclusion

In conclusion, blown in insulation between floor joists is an effective and efficient way to improve the energy efficiency of a building. It helps to reduce heat loss and can also provide soundproofing benefits. Additionally, it is a cost-effective option compared to other insulation methods. However, it is important to ensure proper installation to avoid any potential issues such as settling or moisture problems. Overall, blown in insulation between floor joists is a great choice for improving the comfort and energy efficiency of a building.