Save Money and Stay Warm: The Real Cost to Get Insulation Blown In

Table of Contents

1. Introduction

2. H2: Factors Affecting the Cost of Insulation Blown In

3. H2: Comparing the Cost of Insulation Blown In to Other Insulation Types

4. H2: Tips to Reduce the Cost of Insulation Blown In

5. Q&A

6. Conclusion

Introduction

Insulation blown in—whether fiberglass, cellulose, or mineral wool—offers an affordable, efficient way to seal your home against drafts and energy loss. By filling every nook and cranny, blown-in insulation creates a continuous thermal barrier that keeps you warmer in winter and cooler in summer. But what does it really cost to have insulation blown in? In this article we’ll break down all the factors that influence price, compare blown-in insulation to other options, share money-saving tips, and answer your top questions so you can make an informed decision.

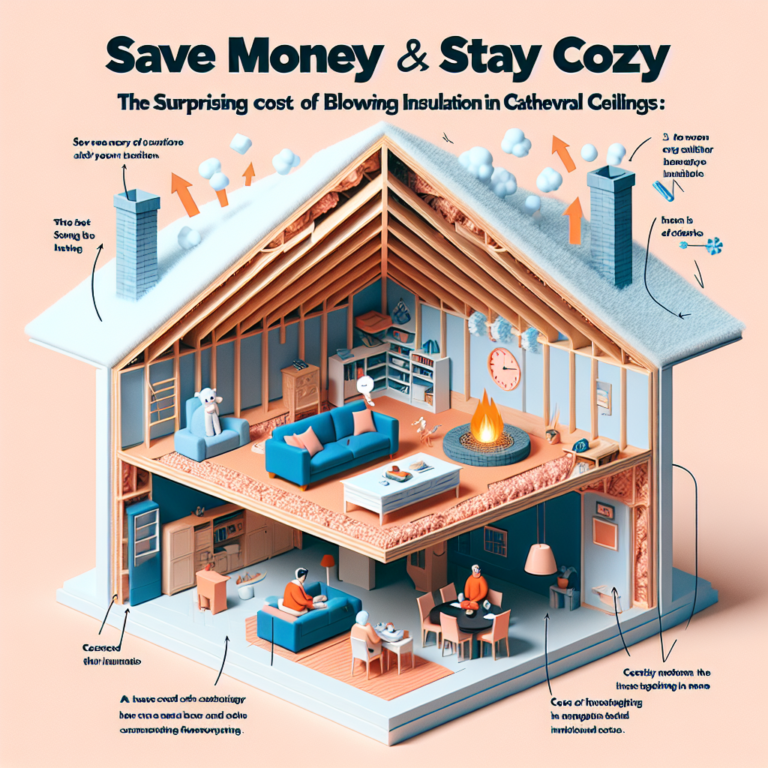

H2: Factors Affecting the Cost of Insulation Blown In

Several key factors determine how much you’ll pay to get insulation blown in:

• Size of the Area: The larger your attic, walls or crawlspace, the more material and labor required. Most installers charge by the square foot or per bag of insulation.

• Type of Insulation: Cellulose (made from recycled paper) runs around $1.50–$3.50 per square foot installed. Fiberglass loose-fill is typically $0.75–$2 per square foot. Mineral wool can cost $1.50–$2.50 per square foot.

• Installation Method: “Loose-fill” is less expensive and fast in open attics. “Dense-pack” requires higher density and more precise installation behind walls, adding to labor costs.

• Existing Insulation: Removing old, damaged insulation can tack on $0.50–$2 per square foot. In some cases you can blow new insulation over existing layers to save removal fees.

• Accessibility and Complexity: Tight spaces, odd angles, or obstacles like ductwork and wiring slow installers down. Expect increased labor if your attic hatch is small or if the project requires ladders, scaffolding, or extra prep.

• Regional Labor Rates: Labor rates vary by region—higher in urban areas or regions with high living costs.

• Time of Year: Demand for insulation peaks in winter and early spring. Off-season scheduling may secure discounts or promotional rates.

H2: Comparing the Cost of Insulation Blown In to Other Insulation Types

How does blown-in insulation stack up against alternatives?

Insulation Type Average Installed Cost per Square Foot R-Value per Inch Pros Cons

Blown-In Cellulose $1.50–$3.50 R-3.2 to R-3.8 • Eco-friendly (recycled) • Fills gaps & crevices • Good sound control Can settle over time; may require topping up

Blown-In Fiberglass $0.75–$2.00 R-2.2 to R-2.7 • Moisture resistant • Non-combustible • Pest resistant Lower R-value per inch; can shift in walls

Spray Foam (Open Cell) $1.50–$3.00 R-3.5 to R-4.0 • Air seal • High R-value • Moisture barrier Higher cost; requires professional certification

Fiberglass Batts $0.50–$1.50 R-2.9 to R-3.8 • DIY-friendly • Low material cost Gaps at seams; less effective in irregular spaces

Mineral Wool Batts $1.00–$2.00 R-3.7 to R-4.2 • Fire resistant • Moisture resistant Higher material cost; labor-intensive cut & fit

Blown-in options often provide better coverage in irregular spaces and can be more cost-effective than spray foam. While batts are cheaper upfront, they may leave gaps that reduce overall performance.

H2: Tips to Reduce the Cost of Insulation Blown In

You don’t have to overspend to enjoy the benefits of insulation blown in. Try these cost-cutting strategies:

1. Get Multiple Quotes

Request at least three detailed estimates. Compare material grades, labor rates, and warranties. Beware of bids that seem too low—they may use inferior materials or skimp on labor.

2. Consolidate Projects

If you’re already updating siding, roofing, or HVAC, bundle insulation with these projects. Contractors may offer package discounts when you combine services.

3. Prep the Space Yourself

Clear out storage from the attic, remove debris, and seal obvious air leaks around vents and plumbing. This reduces labor time and lets installers focus on the insulation itself.

4. Schedule During Off-Peak Seasons

Late spring through summer often features lower demand. Contractors may offer discounts or flexible scheduling to fill their calendar.

5. Seek Rebates and Incentives

Check local utility companies, state energy offices, and federal tax-credit programs. You may qualify for rebates, grants, or tax deductions that offset insulation costs.

6. Opt for Partial Upgrades

If budget is tight, prioritize the most heat-loss areas—like an uninsulated attic floor—before insulating walls or crawlspaces.

Q&A

Q1. What’s the average cost to get insulation blown in?

A1. National averages range from $0.75 to $3.50 per square foot installed, depending on material and method. A typical 1,500 sq. ft. attic might cost $1,200–$4,500 total.

Q2. How quickly will blown-in insulation pay for itself?

A2. Most homeowners recoup the cost in energy savings within 3–7 years, depending on climate, energy prices, and existing insulation levels.

Q3. Can I DIY insulation blown in?

A3. You can rent a blower machine and install in open attics, but walls and dense-pack installations are best left to professionals for proper coverage and compaction.

Conclusion

Investing in insulation blown in is one of the most cost-effective ways to boost your home’s energy efficiency and year-round comfort. From understanding the factors that impact installation costs to comparing blown-in options with other insulation types, you now have the insights needed to plan your project. By gathering multiple quotes, tackling prep work yourself, and tapping into rebates, you can secure affordable comfort without compromising quality. Make today the day you seal in savings and stay warm all season long!