Revolutionize Your Home with Blown Floor Insulation: The Power of Measuring Sticks

Introduction

Chilly floors and soaring energy bills can turn any cozy home into a drafty space. Blown floor insulation offers a modern solution by filling gaps between floor joists with loose fibers—cellulose, fiberglass or mineral wool—pumped in by specialized equipment. When paired with precise measuring sticks, blown floor insulation transforms your home’s comfort, cuts heating and cooling costs, and even quiets noise between levels. In this article, we’ll explore how blown floor insulation works, why accurate measurement is critical, and how the humble measuring stick ensures you get every benefit possible.

H2: The Benefits of Blown Floor Insulation

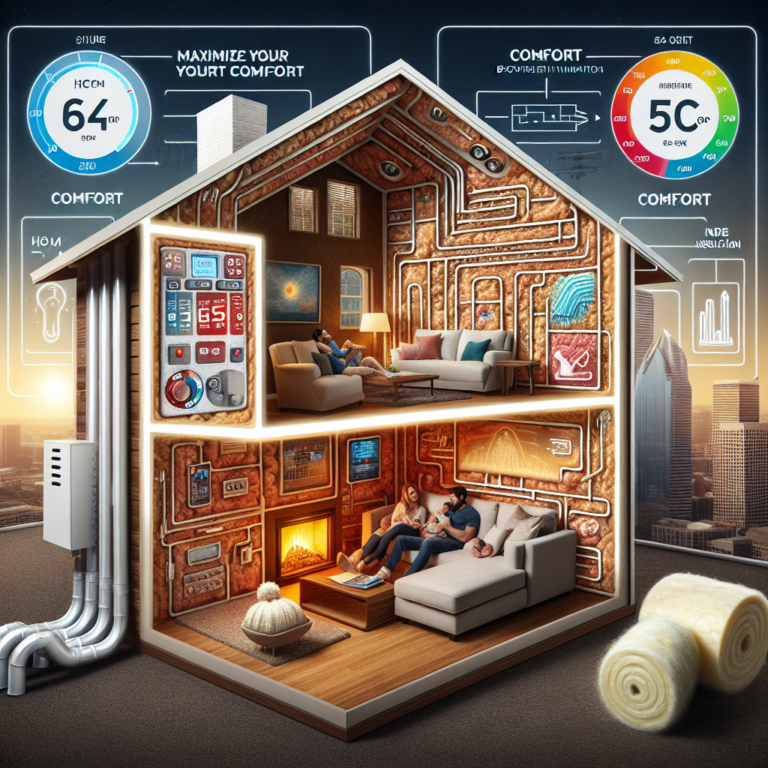

1. Superior Energy Efficiency

• Complete Coverage: Unlike batt insulation that can leave voids, blown floor insulation conforms to every nook and cranny, eliminating drafts.

• Year-Round Savings: Properly insulated floors help maintain stable indoor temperatures, reducing the workload on your HVAC system and trimming energy bills.

2. Enhanced Comfort

• Warm Floors in Winter: A continuous insulation layer prevents cold spots and chilly drafts underfoot.

• Cooler Summers: Reflective fibers slow heat transfer, keeping lower levels more comfortable.

3. Noise Reduction

• Sound Dampening: The loose-fill material absorbs airborne and impact noise—ideal for multi-level homes, offices or rental properties.

4. Environmental Responsibility

• Recycled Content: Cellulose insulation often contains up to 85% recycled paper, while fiberglass and mineral wool use substantial recycled glass or slag.

• Longevity: Properly installed blown floor insulation can last for decades without settling, reducing waste and replacement needs.

5. Increased Home Value

• Market Appeal: Energy-efficient features are top priorities for buyers. Blown floor insulation, accurately installed, becomes a strong selling point.

• ROI: Lower utility bills and improved comfort translate into long-term savings that often exceed installation costs.

H2: How to Properly Measure for Blown Floor Insulation

Accurate measuring is the cornerstone of a successful blown floor insulation project. Follow these steps:

1. Choose the Right Insulation Type

• Loose-Fill vs. Dense-Pack: Loose-fill (cellulose or fiberglass) suits attics and open floor cavities, while dense-pack (higher density cellulose) offers superior R-values in walls and floors.

2. Calculate Square Footage

• Measure Length × Width: Record the total floor area. Include closets, storage areas or mechanical chases.

• Account for Obstructions: Subtract space occupied by pipes, ducts or wiring to avoid over-ordering.

3. Determine Desired R-Value

• Climate Guidelines: Consult local building codes or ENERGY STAR® recommendations for your region.

• Manufacturer Specifications: Each insulation material has an R-value per inch—use these figures to compute required thickness.

4. Estimate Insulation Volume

• Cubic Feet Needed: Divide total square footage by the R-value per inch, then multiply by desired thickness in inches.

• Add 10% Buffer: Always order slightly more insulation to cover settling and minor miscalculations.

H2: Why Measuring Sticks Are Essential for Blown Floor Insulation

Measuring sticks—or depth gauges—might look simple, but they’re indispensable for achieving the right depth and performance:

1. Precision Depth Control

• Visual Reference: Calibrated marks show when you’ve reached the target thickness, ensuring you hit the specified R-value.

• Prevent Over- or Under-Insulation: Too much compression lowers R-value; too little leaves gaps and cold spots.

2. Uniform Distribution

• Consistent Coverage: Measuring sticks guide installers as they move across the floor, delivering an even layer from joist to joist.

• Minimize Rework: Accurate installation reduces the need for costly adjustments or re-blowing.

3. Time and Cost Efficiency

• Faster Installations: Clear depth indicators let crews work quickly without stops for guesswork.

• Material Savings: Precise measurement avoids wasteful over-application or emergency top-offs.

4. Quality Assurance

• Documentation: Inspectors and homeowners can verify correct insulation depth before walls or subfloors are closed up.

• Peace of Mind: Knowing you’ve met or exceeded recommended R-values protects your investment.

H2: Frequently Asked Questions about Blown Floor Insulation

Q1: What is blown floor insulation?

It’s a loose-fill insulation method where fibers—cellulose, fiberglass or mineral wool—are blown into floor cavities to create an even thermal barrier.

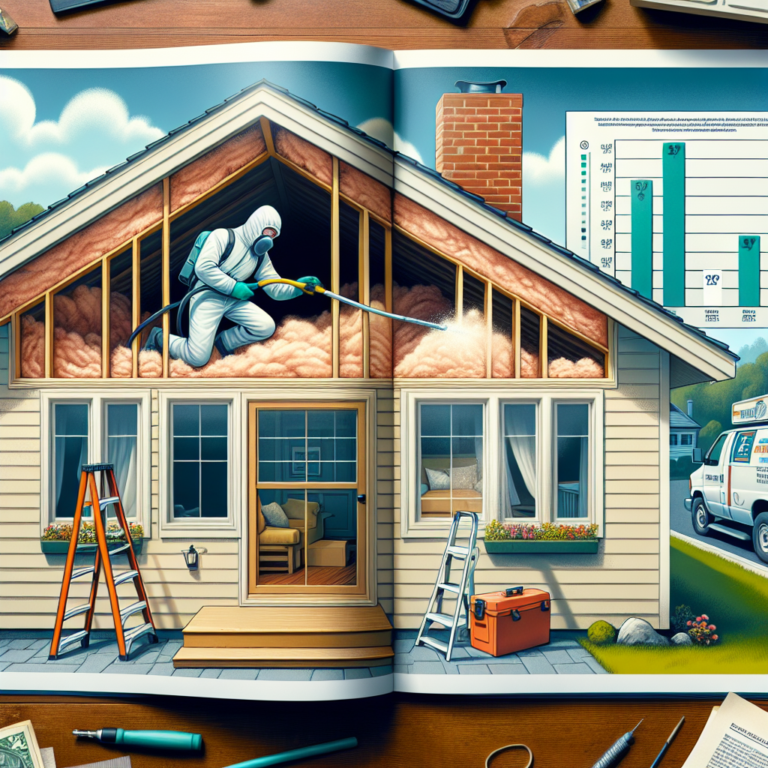

Q2: How is it installed?

Installers drill small holes in the subfloor, insert a hose connected to a blowing machine, and fill the space until depth gauges confirm proper coverage.

Q3: How thick should the insulation be?

Thickness depends on material R-value per inch and local climate requirements. Most homes need R-30 to R-60 in floor cavities.

Q4: How long does it last?

With quality materials and correct installation using measuring sticks, blown floor insulation can last 20–30 years or more without significant settling.

Q5: Will it reduce noise?

Yes—its loose, fibrous structure dampens both airborne sounds and impact noise between floors.

Conclusion

Say goodbye to cold floors, drafty rooms, and high energy bills—revolutionize your home with blown floor insulation. By following proper measurement techniques and leveraging the precision of measuring sticks, you’ll ensure complete coverage, optimal R-values, and lasting comfort. Whether you’re updating an older home or building new, blown floor insulation delivers energy savings, noise reduction, and a greener footprint. Embrace the power of measuring sticks and transform your floors into an efficient, cozy foundation for every step you take.