-

Table of Contents

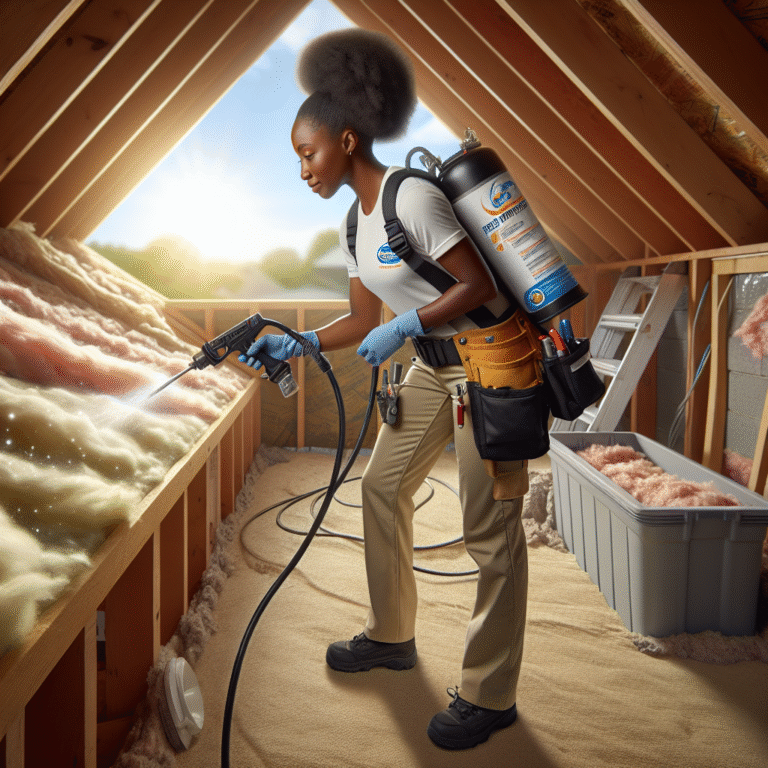

“Efficiently insulate your attic with blown in cellulose – keeping your home comfortable and energy efficient all year round.”

Introduction

Blown-in cellulose attic insulation is a type of insulation material that is commonly used in attics to improve energy efficiency and reduce heating and cooling costs. It is made from recycled paper fibers that are treated with fire retardants and insect repellents, making it a safe and environmentally friendly option for insulation. This type of insulation is installed by blowing it into the attic space, filling in any gaps and creating a barrier against heat transfer. It is a popular choice for homeowners looking to improve the insulation in their attics and create a more comfortable and energy-efficient living space.

The Benefits of Blown-In Cellulose Attic Insulation: A Cost-Effective Solution

Blown-in cellulose attic insulation is a cost-effective solution for homeowners looking to improve the energy efficiency of their homes. This type of insulation is made from recycled materials, making it an environmentally friendly option. In addition to being eco-friendly, blown-in cellulose insulation offers a range of benefits that make it a popular choice among homeowners.

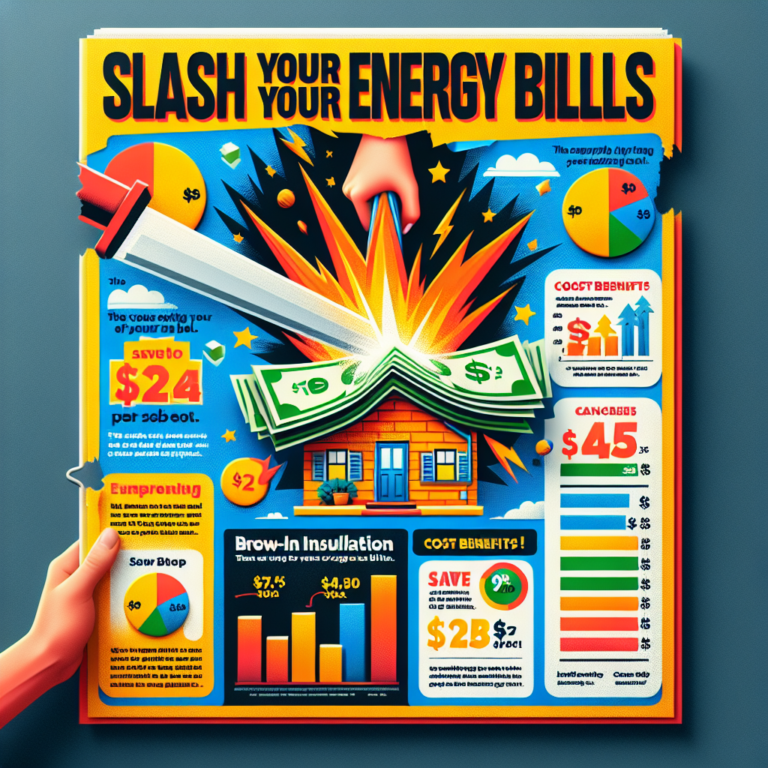

One of the main benefits of blown-in cellulose attic insulation is its cost-effectiveness. This type of insulation is relatively inexpensive compared to other types, such as fiberglass or spray foam. This makes it a great option for homeowners on a budget who still want to improve the energy efficiency of their homes. Additionally, blown-in cellulose insulation can be installed quickly and easily, saving homeowners both time and money on installation costs.

But cost-effectiveness is not the only advantage of blown-in cellulose attic insulation. This type of insulation also offers superior thermal performance. It has a higher R-value, which is a measure of an insulation material’s ability to resist heat flow, compared to other types of insulation. This means that blown-in cellulose insulation can effectively keep your home warm in the winter and cool in the summer, reducing your energy bills and making your home more comfortable year-round.

Another benefit of blown-in cellulose insulation is its ability to reduce noise. This type of insulation is denser than other types, which helps to block out sound from outside. This can be especially beneficial for homeowners who live in noisy areas or near busy roads. Blown-in cellulose insulation can help create a quieter and more peaceful living environment.

In addition to its cost-effectiveness and thermal performance, blown-in cellulose attic insulation is also a sustainable option. As mentioned earlier, this type of insulation is made from recycled materials, such as shredded newspaper and cardboard. This means that it not only reduces waste but also reduces the need for new materials to be produced. By choosing blown-in cellulose insulation, homeowners can contribute to a more sustainable future.

Furthermore, blown-in cellulose insulation is also a safe option for homeowners. It is treated with fire-retardant chemicals, making it resistant to fire. This can provide homeowners with peace of mind, knowing that their homes are protected in case of a fire. Additionally, blown-in cellulose insulation is also resistant to mold and pests, making it a healthier option for homeowners and their families.

One of the unique benefits of blown-in cellulose attic insulation is its ability to fill in small gaps and crevices. Unlike other types of insulation, which may leave gaps or spaces, blown-in cellulose insulation can be blown into even the smallest and hardest to reach areas. This ensures that your home is fully insulated, providing maximum energy efficiency.

In conclusion, blown-in cellulose attic insulation offers a range of benefits that make it a cost-effective and sustainable option for homeowners. Its thermal performance, noise reduction, and safety features make it a popular choice among homeowners looking to improve the energy efficiency of their homes. Additionally, its ability to fill in small gaps and crevices makes it a more effective option compared to other types of insulation. By choosing blown-in cellulose insulation, homeowners can not only save money on energy bills but also contribute to a more sustainable future.

Maximizing Energy Efficiency with Attic Spray Insulation: A Comparison of Cellulose and Other Materials

When it comes to maximizing energy efficiency in your home, one area that often gets overlooked is the attic. However, the attic is actually a crucial space when it comes to keeping your home comfortable and reducing energy costs. One of the most effective ways to improve energy efficiency in the attic is by using blown-in cellulose insulation. In this article, we will explore the benefits of blown-in cellulose attic insulation and compare it to other materials commonly used for attic insulation.

First, let’s define what blown-in cellulose insulation is. Cellulose insulation is made from recycled paper products, such as newspapers, and is treated with fire-retardant chemicals. It is then blown into the attic using specialized equipment, filling in all the nooks and crannies to create a seamless layer of insulation. This method of installation allows for a more thorough coverage compared to traditional batt insulation, which can leave gaps and spaces for air to escape.

One of the main benefits of blown-in cellulose insulation is its high R-value. R-value is a measure of an insulation material’s ability to resist heat flow, and the higher the R-value, the better the insulation. Cellulose insulation has an R-value of 3.2-3.8 per inch, which is higher than other commonly used materials such as fiberglass batts (R-value of 2.2-3.8 per inch) and spray foam (R-value of 3.5-6.5 per inch). This means that blown-in cellulose insulation provides better thermal resistance, keeping your home warmer in the winter and cooler in the summer.

Another advantage of blown-in cellulose insulation is its ability to reduce air leakage. Air leakage is a major contributor to energy loss in homes, and it can account for up to 40% of a home’s energy consumption. The seamless coverage of blown-in cellulose insulation helps to seal any gaps or cracks in the attic, preventing air from escaping and reducing the workload on your heating and cooling systems. This not only improves energy efficiency but also helps to maintain a more consistent temperature throughout your home.

In addition to its energy-saving properties, blown-in cellulose insulation is also environmentally friendly. As mentioned earlier, it is made from recycled paper products, making it a sustainable choice for insulation. It also has a lower carbon footprint compared to other materials, as it requires less energy to produce and transport. Furthermore, the fire-retardant chemicals used in cellulose insulation are non-toxic and safe for both humans and the environment.

Now, let’s compare blown-in cellulose insulation to other commonly used materials for attic insulation. Fiberglass batts, while cheaper than cellulose insulation, are not as effective in reducing air leakage and have a lower R-value. This means that you would need a thicker layer of fiberglass batts to achieve the same level of insulation as blown-in cellulose. Spray foam, on the other hand, has a higher R-value but is more expensive and can be difficult to install properly. It also has a higher carbon footprint and may release harmful chemicals during installation.

In conclusion, blown-in cellulose attic insulation is a highly effective and environmentally friendly option for maximizing energy efficiency in your home. Its high R-value, ability to reduce air leakage, and sustainable production make it a superior choice compared to other materials. While it may be slightly more expensive than fiberglass batts, the long-term energy savings and environmental benefits make it a worthwhile investment. So, if you’re looking to improve the energy efficiency of your home, consider blown-in cellulose insulation for your attic.

Blown-In Cellulose Attic Insulation: Installation Process and Cost Breakdown

Blown-in cellulose attic insulation is a popular choice for homeowners looking to improve the energy efficiency of their homes. This type of insulation is made from recycled paper and is blown into the attic space using specialized equipment. It is a cost-effective and environmentally friendly option for insulating your attic, and in this article, we will discuss the installation process and cost breakdown of blown-in cellulose attic insulation.

The first step in the installation process is to prepare the attic space. This involves clearing out any debris or old insulation that may be present. It is important to have a clean and even surface for the blown-in cellulose insulation to be installed on. Any gaps or holes in the attic should also be sealed to prevent air leakage.

Once the attic is prepared, the installation process can begin. The cellulose insulation is typically blown into the attic using a large hose connected to a machine. The machine breaks down the cellulose fibers and blows them into the attic space, filling in all the nooks and crannies. This method ensures that the insulation is evenly distributed and provides maximum coverage.

One of the advantages of blown-in cellulose insulation is that it can be installed over existing insulation. This means that if you already have fiberglass or another type of insulation in your attic, you can simply add blown-in cellulose on top of it. This can help improve the overall R-value (a measure of insulation’s ability to resist heat flow) of your attic and provide better energy efficiency.

The cost of blown-in cellulose attic insulation can vary depending on the size of your attic and the thickness of the insulation. On average, the cost can range from $1 to $1.50 per square foot. This may seem like a significant investment, but the long-term savings on energy bills make it a worthwhile expense. Additionally, many utility companies offer rebates or incentives for installing energy-efficient insulation, which can help offset the cost.

Another factor that can affect the cost of blown-in cellulose insulation is the depth or thickness of the insulation. The recommended depth for blown-in cellulose insulation is between 12-14 inches. This provides an R-value of around R-38, which is the recommended level for attics in most climates. However, if you live in a colder climate, you may want to consider adding more insulation to achieve a higher R-value.

In addition to the cost of the insulation itself, there may be additional costs for labor and equipment. It is recommended to hire a professional contractor for the installation of blown-in cellulose insulation. They have the expertise and equipment to ensure that the insulation is installed correctly and provides maximum energy efficiency. The cost of labor can vary depending on the contractor and the complexity of the job.

In conclusion, blown-in cellulose attic insulation is a cost-effective and environmentally friendly option for insulating your attic. The installation process involves preparing the attic space and blowing the insulation in using specialized equipment. The cost of blown-in cellulose insulation can vary depending on the size of your attic, the thickness of the insulation, and any additional labor costs. However, the long-term savings on energy bills make it a worthwhile investment for any homeowner looking to improve the energy efficiency of their home.

Q&A

1. What is blown in cellulose attic insulation?

Blown in cellulose attic insulation is a type of insulation material made from recycled paper fibers that is blown or sprayed into attic spaces to provide thermal insulation.

2. How does blown in cellulose attic insulation compare to other types of insulation?

Blown in cellulose attic insulation has a higher R-value (a measure of thermal resistance) compared to other types of insulation, meaning it provides better insulation and can help reduce energy costs. It is also more environmentally friendly as it is made from recycled materials.

3. What are the benefits of using blown in cellulose attic insulation?

Some benefits of using blown in cellulose attic insulation include improved energy efficiency, reduced noise transmission, and better fire resistance compared to other types of insulation. It is also easy to install and can fill in small gaps and crevices, providing better coverage and reducing air leakage.

Conclusion

In conclusion, blown-in cellulose attic insulation is a highly effective and efficient method of insulating attics. It is made from recycled materials and has a high R-value, providing excellent thermal resistance. This type of insulation is also easy to install and can fill in small gaps and crevices, creating a more airtight seal. Additionally, blown-in cellulose insulation is resistant to mold and pests, making it a durable and long-lasting option for attic insulation. Overall, it is a cost-effective and environmentally friendly choice for improving the energy efficiency and comfort of a home.